ROTARY DRYER

INDUSTRIAL ROTARY DRYERS:

We Have Built A Character On Manufacturing The Best And Most Suitable Rotary Dryer Systems With Reasonable PriceTo Our Customer In Industries. All Shiva Techno Fab’s Dryers Are Manufacture On The Base Of Custom Designed To Suit The Unique Processing Needs Of Your Material. According To The Special Features Of Raw Material Needed To Be Dried, Shiva Techno Fab Can Design And Supply The Suitable And Reasonable Rotary Dryer Machines For The Customers Accordingly As Actual Need. We Consider All The Small Details Of Your Material Like Required Low Or High Temperature In Inlet, Residence Time, Counter Current Or Co-current Flow, Material Properties Etc. We Have Highly Experience Team Who Have Years Of Technical And Design Knowledge. We Understand The Client Requirement And Shiva Techno Fab’s Design Team Can Design A Rotary Dryer For Your Different And Various Material And Application.

APPLICATION OF ROTARY DRYER :

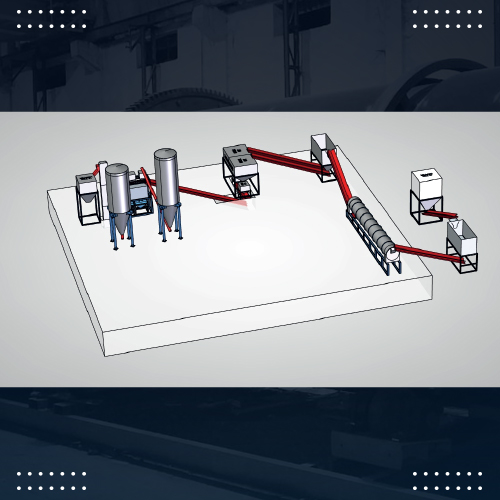

Shiva Techno Fab Since Working With 7 years Experience In Domestic And International Market With Vast Range Of Products Like Dryer, Classifying, Crushing, Milling, Grading And Material Handling Equipment In Major Range Of Applications Or Industries.Rotary Dryers Are Use For The Dryer Various Material Like River Sand, Silica Sand, Garnet Sand, Quartz Sand, Pond/Fly Ash,Pozzolana Ash, slag Sand, Minerals, Chemicals, Sawdust, Wood Chips, Sludge, Bagasse, Etc. Shiva Techno Fab’s Rotary Dryers Works By Gripping Material In A Rotary Drum In Presence Of Direct Hot Air. We Are Also Use Indirect Hot Air To Avoid Direct Contact Between The Material And Processing Medium. The Rotary Dryer Drum Is Located At A Slight Horizontal Slop To Allow Gravity To Help In Moving Material Through Drum. When The Rotary Dryer’s Drum Starts Rotating Lifting Flights Lift The Material And Drop It Through The Air Stream In Order To Maximize Heat Transfer Efficiency. Material Is Processed For A Specified Amount Of Time, Referred To As The Retention Time, At The Desired Temperature, In Order To Produce A Product With The Required Moisture Content. While Rotary Dryers Are Available In Standardized Models, Designing A Rotary Dryer Around The Unique Characteristics Of The Material And Process Needs Will Produce The Best Results And Offer The Most Reliability. Various Aspects Of The Dryer Are Considered During Initial Design In Order To Reach The Exact Desired Parameters Of The End Product.

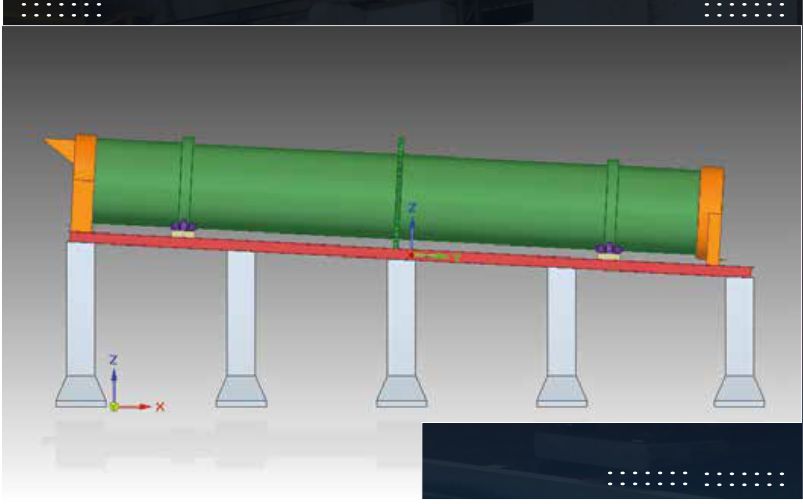

CONSTRUCTION OF ROTARY DRYER :

Rotary Dryer Mainly Consist Of Shell (Drum), Inlet Hood, Outlet Hood, Girth Gear, Riding/Tire Ring, Pinion, Trunnion Wheel, Thrust Roller, Transmission Assembly, Burner/Hot Air Generator, Induced Draft Fan, Raw Product Inlet Hopper, Product Discharge, Flights, Air Seals, Rav, Cyclone Separator, Aluminum And Cerawool Claddings.

KEY FEATURE :

- Size: Dia X Length

- Capacity: 1 Tph To 70 Tp

- Specially Design For Maximum Heat Transfer Between The Material And Hot Air/Gas Stream.

- Heavy Duty Design And Construction

- Trusted Many Years Of Services

- Counter And Co-current Configuration

- De-dusting Equipment

MATERIAL OPTION :

- Carbon Steel

- Mild Steel

- Stainless Steel

- Ms/ss Cladded

VARIOUS TYPE OF FUEL

- LDO/Diesel/FO

- coal

- Wood

- Gas Fired (LPG/NATURAL GAS, PNG)