MIXING UNIT

We Are Engaged In Manufacturing, Supplying And Exporting Of A Wide Range Of Mixing Equpment / Machinery. Under This Category We Offer A Range Of Products That Includes Ribbon Blender, Plough Shear Mixer, Pan Mixer And Many More. All The Machines Offered By Us Are Designed And Manufactured Using High Quality Raw Material And Components. Our Customers Can Also Avail From Us A Wide Range Of Customized Versions Of These Products Made In Accordance To The Clients' Specifications. Quality And Efficiency Are Critical When It Comes To Mixing Operations In A Bioprocessing Environment, And The Choice Of Mixing Equipment Can Dramatically Affect Both. In Fact, A Fast And Flexible Single-use Mixer Can Be A Competitive Advantage, Helping Manufacturers Maximize Throughout And Increase The Production.

RIBBON BLENDER :

Shiva Techno Fab’s Ribbon Blenders Is Design To Provide High Mixing Efficiency, Blending Small Proportions Into Large Stocks. It Is Primarily Designed For Use With Dry Materials, Although Gas And Liquid Streams Can Also Be Introduced. A Wide Variety Of Configurations, For Either Batch Or Continuous Mixing, Are Available. Application Specific Rotor Mixing Element Design Allows Shorter Batch Cycle Times Due To Increased Mixing Efficiency. Efficient Mixing Also Provides Good Heat Transfer Through Optional Asme Code Designed Jackets For Heating Or Cooling Applications. The Compact And Robust Construction Dust Proof Operation Ensures Their Negligible Running Costs. We Can Offer These In Various Customized Sizes/finishes. We Provide Customized Design Of The Ribbon Blender To Meet Your Specific Mixing Requirements. The Classic Ribbon Blender Serves Multi-purpose Uses In The Manufacture Of Construction, Food, Beverage, Pharmaceutical, Cosmetic, Chemical, Plastic, Agricultural And Other Products.

PAN MIXER :

We Have Been Offering Premium Quality Equipment To Our Clients Over A Span Of Time. This Has Been Possible Only Because Of Our Strict Quality Measures Which Make Us Different From Others. Shiva Techno Fab Offers You A Comprehensive Range Of Pan Mixers. These Are Solidly uilt With Heavy Steel Bottom And Rollers With Hydraulic Door Open. The Machines Have The Capacity To Finely Pulverize And Blend Materials Such As Cement, Fly Ash And Small Granules. The Machine Can Be Relocated Easily. These Mixers, Further Offer Smooth Operation And Long-lasting Performance. Innovation Is Our Forte And We Strive To Design And Develop Concrete Pan Mixer. Quality Components And Advanced Technologies Are Widely Implied By The Experts Of Our Firm In Manufacturing These Mixers.

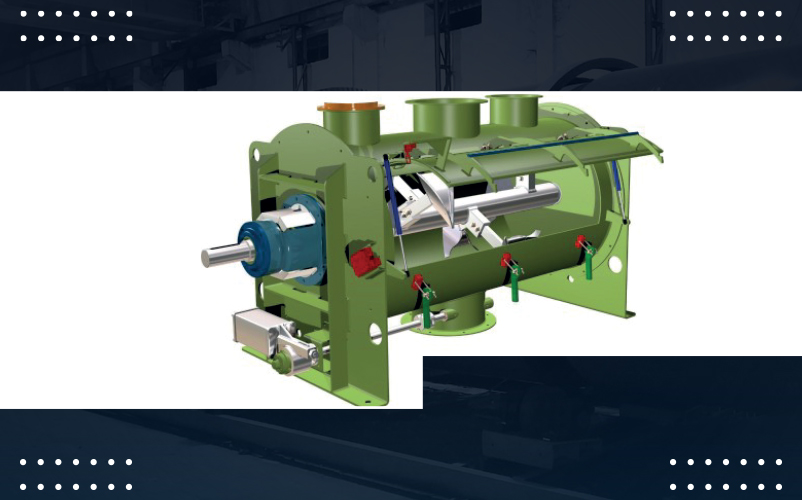

PLOUGH SHEAR MIXER :

Shiva Techno Fab’s Plough Mixer Consists Of Horizontal & Cylindrical Drum Vessel, Plough Shaped Shovel Agitator, Drive Unit And Chopper. The Mixing Elements Create A Mechanical Fluidized Bed Mixing Actions To Hurl Materials Away From The Wall Of Vessel Into Free Space In Crisscross Direction And Inversely Back Again. A Fluid Bed Generated Mechanically In This Way, Whereby The Raw Material Is Constantly Involved In The Mixing Process, Ensures Maximum Mixing Intensity At Even The Highest Feed Rates And Shortest Residence Times And Allows Addition Of Liquids. The Ploughshare Mixer Guarantees Extremely High Performance And Fully Optimized Processes To Adapt Specific Mix. Plow Mixer Has Very Fast Mixing Speed To Get Ideal Mixing Homogeneity In Very Short Time And Can Also Be Used To Solve Multiple Applications Including Mixing, Coating, Reacting In One Single Machine. In Order To Meet Big Capacity Requirement, We Can Also Design Batch And Continuous Mixing Process For Client.