POND/FLY ASH DRYING

SHIVA TECHNO FAB is one of the leading manufacturer and suppliers of Industrial dryers such as Rotary dryer, Sand Dryer, Fly Ash dryer, minerals dryer, Coal Dryer, Biomass Dryer etc. due to business trends, public scrutiny, government regulation, water constraints, etc., coal power plants in India and overseas are endeavor to eliminate their ash ponds and replace them with dry solutions. If you’re considering a transition from wet to dry ash handling, Shiva Techno fab will facilitate.

SHIVA TECHNO FAB has research and technical team , we manufacture Fly ash Drying Systems are custom-designed and made as pr customers requirements.. Our technical team considers all the parameters as like area specifications, foundation ,electricity and future fuel use, storage capability, location, etc.

PRODUCT DESCRIPTION

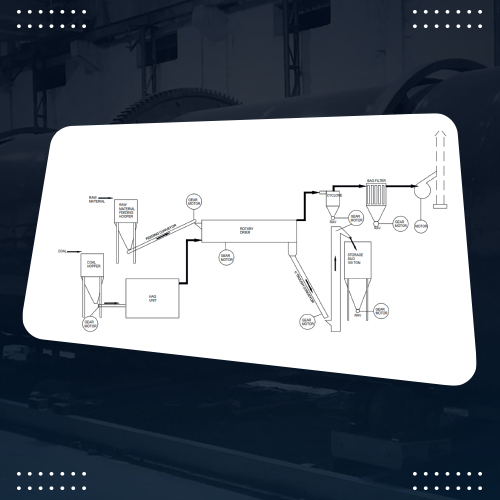

ROTARY DRYER :

Rotary Dryer Mainly Consist Of Shell (Drum), Inlet Hood, Outlet Hood, Girth Gear(En-9), Riding/tire Ring, Assembly, Burner/Hot Air Generator, Induced Draft Fan,Raw Product Inlet Hopper, Product Discharge, Flights, Air Seals, Rav, Cyclone Separator, Aluminum And Cerawool Claddings.

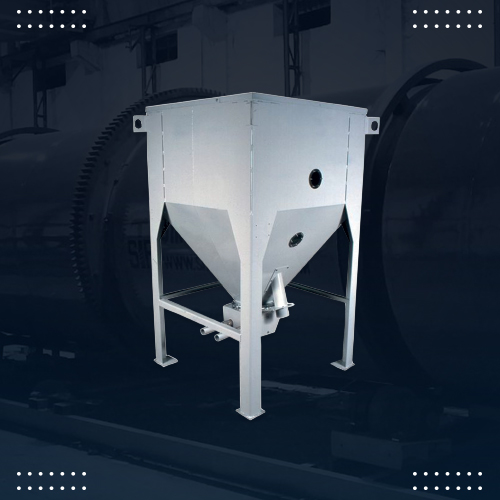

FEEDING HOPPER :

Feed Hopper Is Designed According To The Pond/fly Ash Properties . For Making Smooth Discharge We Are Providing Aeration System & Vibrator System For Free Flow Of Material. From Feed Hopper There Is One Screw Feeder And Weighing Hopper Which Is Commanded Through Plc & Hmi. So The Exact Feeding Should Be Done To The Dryer.

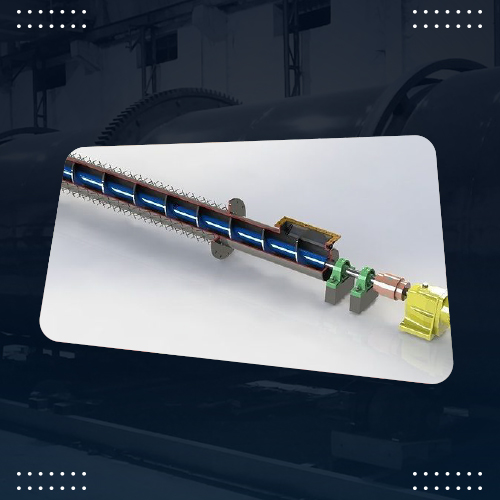

BELT CONVEYOR :

For The Handling Of Wet Fly Ash We Preferred Chevron Belt Conveyor To Deliver The Wet Fly Ash From Feeding Hopper To The Input Of Dryer. Our Belt Conveyor Consist With High Quality Structural Design And Instrumentation Devices Such As Zss, Belt Sway, Pull Cord And Etc. Our Belt Conveyor Is Fully Covered With Aluminium Or Pvc Sheet To Control The Dust.

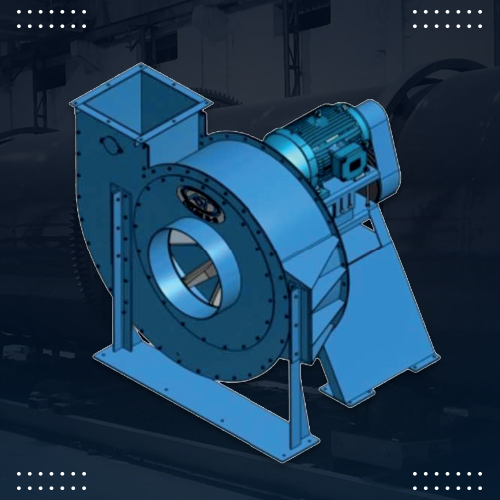

INDUCED DRAUGHT FAN :

We Are Providing The High Efficiency Induced Draft Fan To Remove Moisture From The Dryer And Delivered To The Stack/chimney.

DUST COLLECTOR SYSTEM :

Pulse Jet Bag Filter / Pulse Jet Hose Bag Type Filters Are Known As Conventional De-dusting Filters. Shiva Techno Fab Has Developed New Age De-dusting Designs For This Filters Which Gives Better Life Of Filter Bags, Lower Emission Levels, Lower Pressure Drops, Lower Power Consumption, Higher Air To Cloth Ratios With Better Performance Levels, Lower Floor Space Requirement. Shiva Techno Fab Supplies Customized Bag Filters On The Bases Of Application Requirement. These Pulse Jet Bag Filters Are Used Where Air-flows Are In Large Quantity, Temperatures Are Higher Than Ambient Or Material To Be Handled Is Difficult. The Original Concept Of Fabric Filtration Started Over Century Back & Is Still Valid & Very Practical, For Separation Of Solids From Air/ Gas Stream. Tubular Filter Fabric (Woven & Non-woven) Hose Bags Are Widely Employed World Over, Vertically Placed Within A Housing. For Preventing Collapse Under Vacuum Or Pressure, These Bags Are Retained By Metal Cages Fitted With Venturies.

COAL FIRED DIRECT HEATING SYSTEM :

For The Heating Medium We Gives Hot Air Generator Along With Rotary Dryer System. We Select P.A Fan, Fd Fan, S.F.D Fan According To Plant Location Humidity And Weather. Cause Of That We Gain Up To 90% Efficiency In Our Hot Air Generator.

In Hot Air Generator Fluidized Bed Should Be There. In This Bed Coal Will Spray By Nozzle In The Combustion Area And It’s Create Temperature In Hot Air Generator.produced Air Will Be Transfer In To The Rotary Dryer Inlet. We Provide Instrumentation Devices Like Rtd Sensors,dilution Damper, Screw Feeder ( For Proper Feeding Of Coal Into The Heating Furnace ) For Better Efficiency.

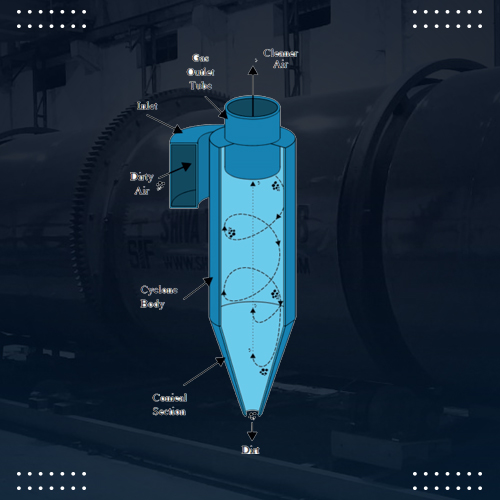

CYCLONE SEPARATOR :

It Is A Dust Collecting System With Cyclonic Waves As Name Resembles It Creates Cyclonic Current To Separate Light Air To Id Fan And Dust To Lower Bottom Collection System Through Rotary Air Lock Valve

Uses Of Fly Ash

The Major Uses Of Fly Ash Are Listed Below:

- Used in the manufacture of portland cement.

- Used as a soil stabilisation material.

- Used in roller compacted cocncrete dams.

- Used in the manufacture of fly ash bricks.

- Used in making building material such as dry mortar, block jointing mortar, ready mix plaster, tile adhesive and grout etc.